AITT TOOLS

AITT (Advanced Interconnect Test Tool) is ideal for signal-integrity and power-integrity applications. The AITT software includes four key functions: analysis, de-embedding, applications, and VNA control. It can be installed on a VNA directly or a PC that controls the VNA remotely.

A Versatile Tool for Interconnect Analysis and PCB Characterization

HIGHLIGHTS

- Features:

- Versatile:

- Analysis Tool

- Frequency domain

- Time domain

- Eye diagram

- De-embedding Tool

- 2X Thru

- 1X Open

- Impedance autocorrection

- Causality/Passivity Tool

- Applications

- PCB material extraction tool

- PCB Delta-L+ tool

- VNA Control

- Easy-to-Use: user-friendly interface

- fast: fast C++ runtime, script-mode support

PacketMicro is an authorized distributor for Clear Signal Solutions. You can download the Advanced Interconnect Test Tool (AITT) and request an evaluation license for free. The evaluation license allows unrestricted access to all of AITT's tools and features for 30 days. To continue using AITT after the evaluation license expires, please contact sales@clearsig.com.

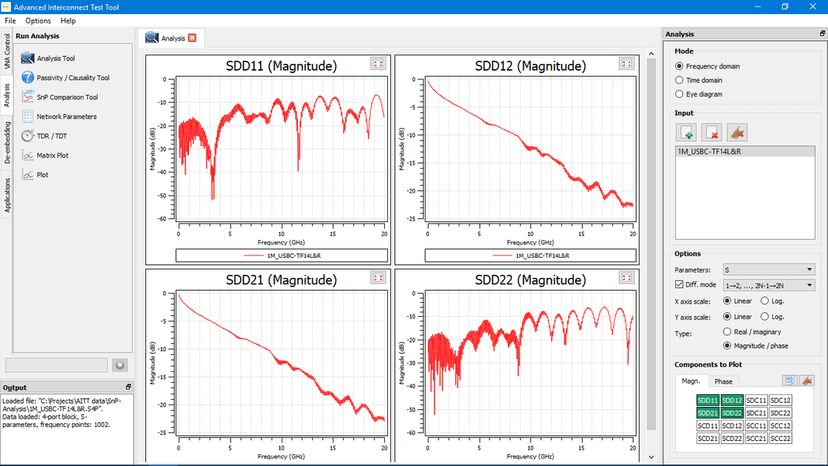

AITT-AR

The AITT-AR analysis tool offers an easy user interface for performing frequency-domain, time-domain, or eye-diagram analysis. Its powerful plot tools allow a user to examine and compare data.

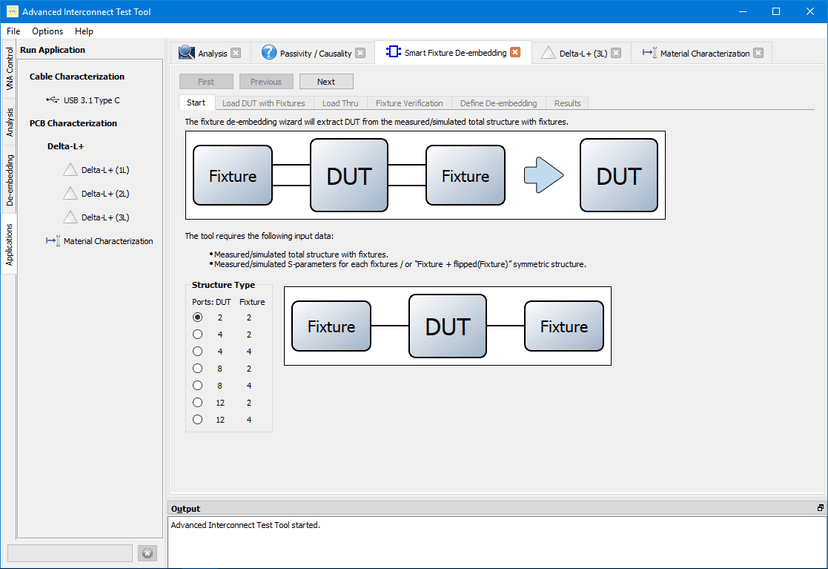

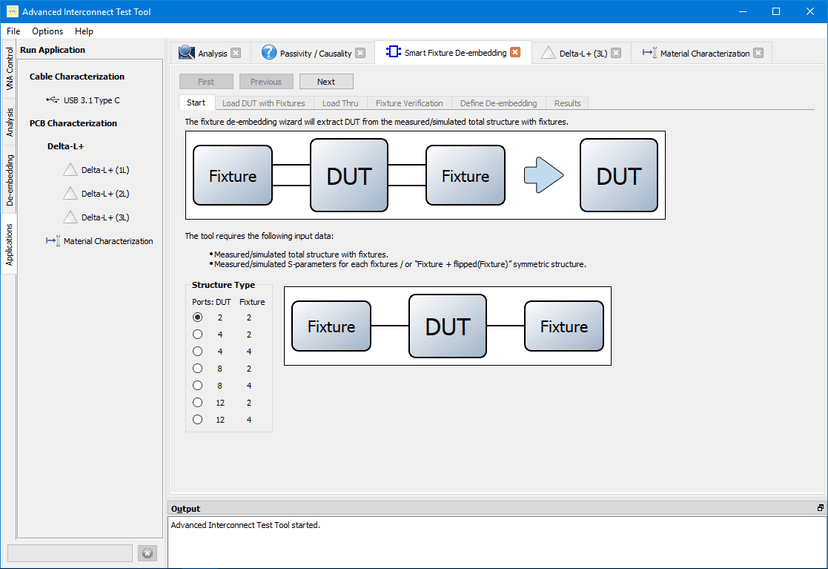

AITT-SFD

For fixture removal applications, the AITT-SFD tool supports the 2X thru, 1X-reflect, and other traditional techniques for extracting network parameters required in modeling of high-speed interconnects, such as circuit board traces and vias, connectors, IC packages, and cables. It can automatically correct the impedance difference between the test fixture and DUT.

AITT-ME (PCB MATERIAL CHARACTERIZATION TOOL)

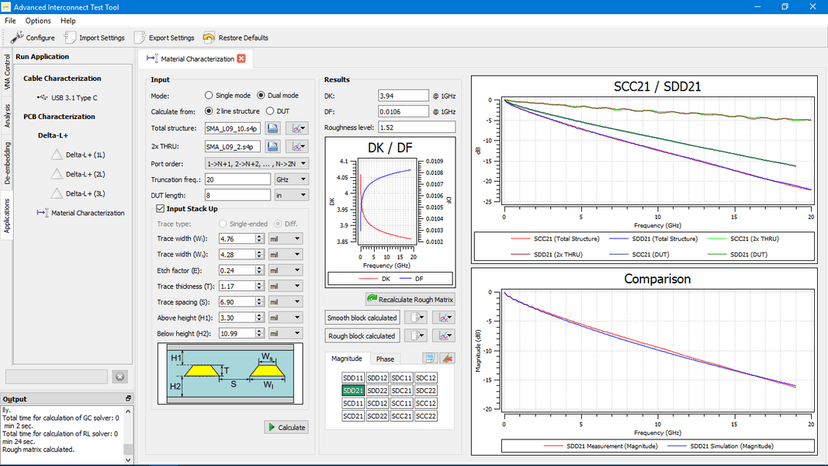

The AITT-ME material extraction tool extracts DK, DF, and surface roughness of a printed-circuit board from S-Parameter measurements of traces on the PCB. Compared to conventional techniques, this approach is simpler and more accurate.

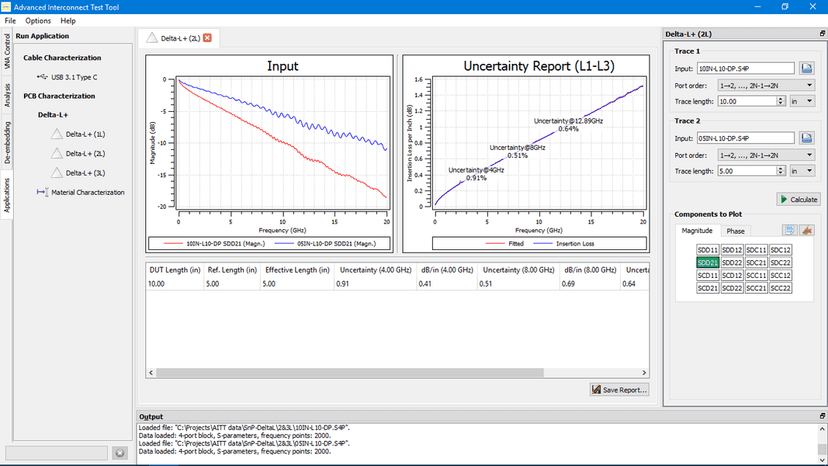

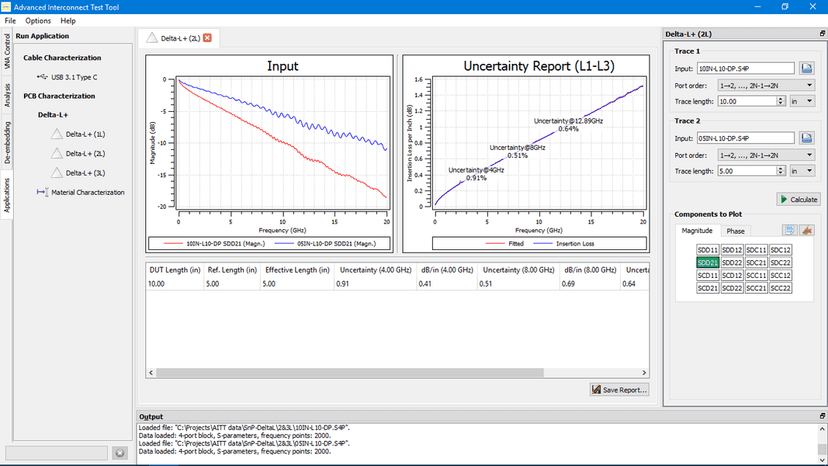

AITT-DL (DELTA-L + PCB CHARACTERIZATION)

The AITT-DL solution guides a user to perform 1L measurements for high-volume manufacturing, 2L measurements for board-quality validation, and 3L measurements for material characterization, as recommended by the Intel Delta-L+ methodology.